FIBC Bag Top Designs play a crucial role in the efficiency and effectiveness of bulk packaging solutions. Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, big bags, or jumbo bags, are essential for transporting various materials across different industries. The FIBC Bag Top Designs significantly impacts its usability, filling speed, and material safety. In this article, we will explore the different types of FIBC bag tops, their benefits, and how to choose the right one for your filling system, with a focus on EPP Vietnam as a reliable supplier.

What is an FIBC Bag Top?

The top of an FIBC (Flexible Intermediate Bulk Container) is the entry point through which materials are loaded into the bag. Depending on the product type and filling method—manual, semi-automatic, or fully automated—the top design must be selected to ensure efficient, dust-free, and safe filling. FIBC tops vary in shape, closure type, and functionality, each suited to specific industrial applications.

Additionally, the choice of top design can significantly impact the handling and transportation of the FIBC. For example, spout tops facilitate precise filling and reduce spillage, while open tops allow for quick loading. Each design also affects how easily the bag can be stacked and stored, influencing overall logistics efficiency.

Why FIBC Bag Top Designs Matters

Choosing the right FIBC bag top designs is essential for optimizing every stage of the filling process. A well-matched top allows faster loading, helping to reduce bottlenecks and improve overall production speed. Proper sealing is equally important, as it prevents product loss and contamination—especially critical when handling fine powders or sensitive materials. Compatibility with your filling equipment is another key factor; whether you’re using gravity-fed systems, pneumatic conveyors, or auger-based fillers, the top design must align seamlessly to ensure smooth operation.

In industries like agriculture, construction, pharmaceuticals, and chemicals, product safety is paramount, particularly when dealing with food-grade or hazardous substances. The right FIBC top not only enhances hygiene but also minimizes downtime, reduces spills, and streamlines workflow. By selecting a tailored top construction, businesses can significantly cut labor costs and boost throughput—making it a smart investment for long-term efficiency.

Top 5 FIBC Bag Top Designs

1. Open Top

Best For: Quick Filling

The open top design allows for rapid loading of bulk materials. This option is particularly advantageous for loose materials like sand, gravel, or agricultural products. The ease of filling makes open top FIBCs ideal for construction sites and agricultural applications where speed is critical. However, it may not provide the best protection against contaminants or moisture.

2. Spout Top

Best For: Controlled Filling

The spout top design features a narrow opening that allows for precise filling. This is one of the popular FIBC Bag Top Designs can be equipped with a petal closure, which helps control the flow of materials, making it suitable for fine powders and granular products. Spout tops are commonly used in the chemical and food industries where accuracy and cleanliness are essential. This construction ensures minimal spillage and maximum efficiency during the filling process.

3. Duffle Top

Best For: Versatility and Protection

Duffle tops consist of a fabric cover that can be easily opened and closed. This design offers flexibility and is suitable for various materials, providing a degree of protection against contaminants. Duffle tops are ideal for applications that require frequent filling and emptying, such as compost or fertilizers. Their adaptability makes them a popular choice in industries where material types may vary.

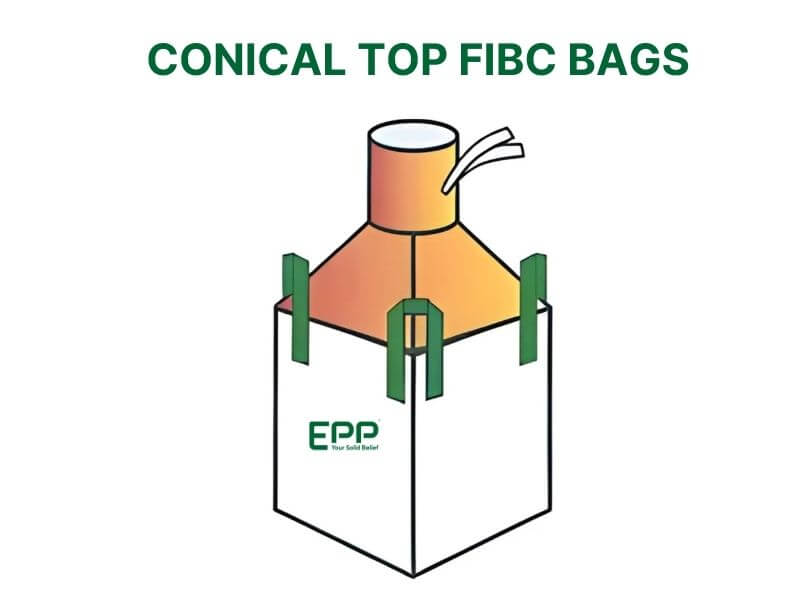

4. Conical Top

Best For: Specialized Applications

Conical tops are designed with a tapered shape that facilitates easy filling and emptying. This design is particularly useful for bulk materials that tend to clump or settle, such as seeds and fertilizers. Conical tops are commonly used in the agricultural sector, allowing for efficient handling of various products. The shape also aids in ensuring that materials flow smoothly during the filling process.

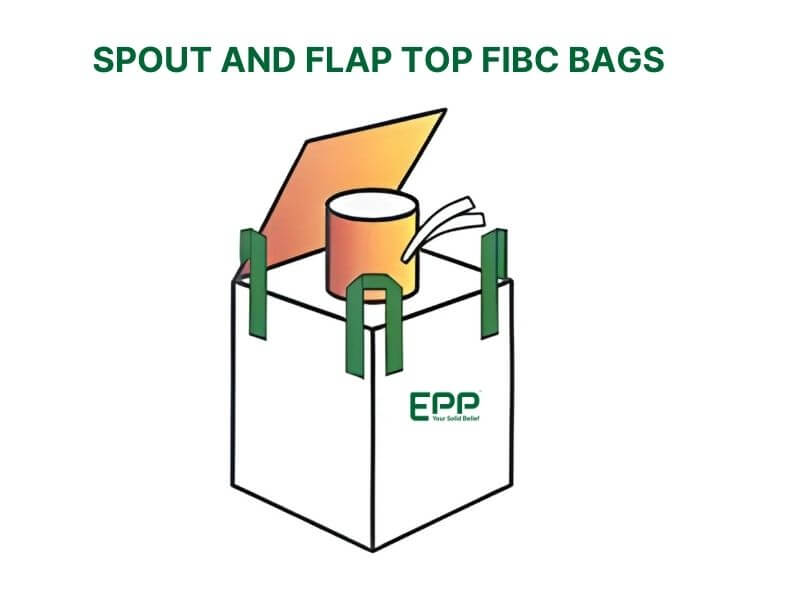

5. Spout Top with Flap

Best For: Maximum Control and Protection

This design combines the advantages of both spout and flap tops, offering precise filling capabilities while ensuring protection against contaminants. The flap can be secured to keep the contents safe during transport. This design is ideal for high-value or sensitive materials, making it suitable for a variety of industrial applications, including chemicals and food products.

How to Choose the Right FIBC Bag Top Designs for Your Filling System

When selecting the appropriate FIBC bag top designs, consider the following factors:

- Type of Material: Assess the characteristics of the material you will be transporting. Fine powders may require spout tops, while bulk aggregates may be better suited for open tops.

- Filling Method: Determine how the bag will be filled. Automated systems may require specific designs for compatibility, such as spout tops or flap tops.

- Environmental Conditions: Consider the storage and transport conditions. If moisture or dust is a concern, opt for designs that provide additional protection.

- Frequency of Use: If the bag will be filled and emptied frequently, a more versatile design like a duffle top may be beneficial.

- Supplier Options: EPP Vietnam offers a variety of FIBC bag top designs and constructions, allowing you to choose the one that best meets your operational needs. With their commitment to quality and sustainability, EPP Vietnam is a reliable source for bulk bags in Vietnam.

Conclusion

Understanding the different FIBC bag top designs is crucial for optimizing your filling system’s efficiency and safety. Whether you require open tops for quick filling or spout tops for controlled dispensing, selecting the right design can significantly enhance your operations. EPP Vietnam stands out as a potential supplier, providing various options tailored to meet the unique demands of your business. By making an informed choice, you can ensure that your bulk packaging solutions are both effective and reliable.