FIBC bags, commonly known as bulk bags or jumbo bags, are essential for transporting and storing a wide variety of materials. The body construction of these bags is critical, as it directly impacts their strength, stability, and suitability for different applications. Understanding the top three best FIBC bag body constructions can help you make informed decisions when selecting the right bag for your needs.

What is FIBC Bags Body Construction?

FIBC bag body construction refers to the design and material configuration that make up the main body of the bag. This construction determines how the bag handles weight, its overall durability, and how it performs during transportation and storage. The choice of body construction can affect factors such as load capacity, stability, and the ability to withstand environmental conditions. Different constructions are tailored to meet specific needs, making it essential to choose the right design for your application.

Why Body Construction Matters in FIBC Bags

The body construction of FIBC bags significantly influences their performance and safety. A well-constructed bag can handle heavy loads without compromising integrity, while a poorly designed bag may fail under pressure, leading to material loss and safety hazards. Additionally, the right construction can enhance the bag’s ability to retain its shape during handling, reducing the risk of spillage. For industries that rely on transporting bulk materials, selecting the appropriate body construction is crucial to ensure efficiency and minimize risks associated with handling and storage.

Top 3 Best FIBC Bags Body Constructions

When it comes to FIBC bags, three body constructions are commonly recognized for their unique benefits: U-panel, Circular, and 4-panel constructions. Each type offers distinct advantages and is suited for various applications.

U-Panel Construction

U-panel construction features a single panel of fabric that forms the front and back of the bag, creating a U-shaped body with two side seams. This design provides excellent stability and strength, making U-panel bags ideal for heavy loads. The U-panel construction effectively distributes weight across the bag, reducing stress on seams and enhancing overall durability.

One of the standout benefits of U-panel construction is its ability to minimize seam failures. The design ensures that the bag maintains its shape even under heavy loads, making it suitable for transporting materials such as sand, gravel, and chemicals. Furthermore, U-panel bags are often easier to fill and empty, adding to their convenience in various industrial applications.

Circular Construction

Circular construction involves a continuous tube of fabric that forms the entire body of the bag, with no vertical seams. This design offers superior strength and flexibility, making circular FIBC bags suitable for a wide range of applications. The seamless nature of circular construction allows for better weight distribution, reducing the risk of weak points that could lead to failure.

One of the primary advantages of circular construction is its ability to maintain a consistent shape under load. This stability is crucial for preventing bulging and ensuring that the bag holds its contents securely. Additionally, circular bags tend to be lighter than other constructions, making them easier to handle and transport, which can enhance operational efficiency.

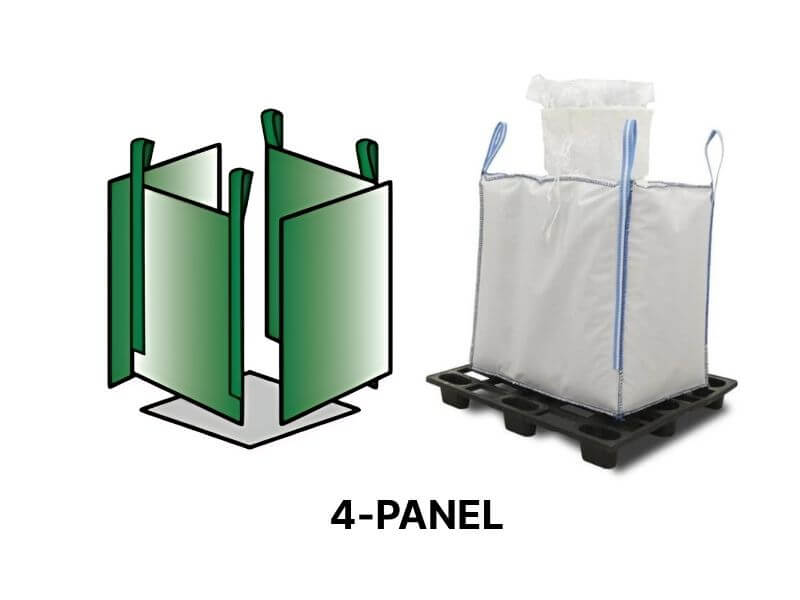

4-Panel Construction

4-panel construction features a design with four separate panels that form the body of the bag. This construction method allows for increased stability and is particularly beneficial for handling shifting materials, such as powders or granules. The design helps maintain the bag’s shape when filled, preventing bulging and ensuring stability during transport.

The key benefit of 4-panel construction is its ability to maximize volume while minimizing the bag’s footprint. This makes it particularly effective for stacking and storage, allowing for efficient use of space in warehouses and shipping containers. Additionally, the design provides a higher degree of stability, reducing the risk of spillage during handling.

How to Choose the Right Construction for Your Needs

Choosing the right FIBC bag body construction depends on several factors, including the type of materials you’re handling, the expected load weight, and specific environmental conditions. Here are some considerations to help guide your decision:

- Material Type: Determine the nature of the materials you will be transporting. For heavy or abrasive materials, U-panel or circular constructions may be more suitable. For lighter, more volatile materials, baffle constructions can provide added stability.

- Load Capacity: Assess the weight of the load. If you need to transport heavy items, opt for U-panel or circular constructions, which offer greater durability and strength.

- Handling Requirements: Consider how the bags will be filled, transported, and stored. If you require ease of handling and stacking, baffle bags may be the best option due to their stability.

- Environmental Conditions: Take into account the conditions the bags will be exposed to, such as UV light or moisture. Some constructions offer better resistance to environmental factors, which can affect the longevity of the bags.

FAQ about FIBC Bags Body Constructions

1. What is the main advantage of U-panel construction?

U-panel construction provides enhanced strength and stability, making it ideal for heavy loads and reducing the risk of seam failure.

2. How do circular FIBC bags differ from other constructions?

Circular FIBC bags feature a seamless design that offers superior flexibility and consistent shape under load, minimizing weak points.

3. What are the benefits of using baffle construction in FIBC bags?

Baffle construction maintains the bag’s shape, preventing bulging and enhancing stability during transport, making it suitable for shifting materials.

4. Can I use any FIBC bag construction for all materials?

Not all constructions are suitable for every type of material. It’s important to choose a design that matches the specific handling and load requirements of your materials.

5. How do I determine the right load capacity for my FIBC bags?

Consult the manufacturer’s specifications for load capacities and ensure that the chosen construction can handle the expected weight of your materials.

Conclusion

Understanding the top body constructions of FIBC bags—U-panel, Circular, and 4-panel Baffle—is essential for selecting the right bag for your needs. Each construction offers unique benefits tailored to specific applications, impacting safety and efficiency during transportation and storage. By considering your material type, load capacity, and handling requirements, you can make informed decisions that enhance your operations. For high-quality FIBC bags tailored to your needs, consider reaching out to reputable suppliers to ensure you get the best solutions for your bulk material handling.