Lifting loops are essential components in the design of FIBC bags, commonly known as bulk bags, big bags, super sacks, and jumbo bags. These loops play a critical role in the safe and efficient handling of these bags, which are widely used across various industries for transporting and storing bulk materials. In this article, we will explore the significance of lifting loops, popular options available, how to choose the right lifting loop, the materials and stitching techniques involved, and address some frequently asked questions.

What Are FIBC Lifting Loops?

FIBC lifting loops are robust straps or handles that are integrated into the structure of flexible intermediate bulk containers (FIBCs). Designed for lifting and transporting heavy loads, these loops allow for safe handling using forklifts, cranes, or other lifting equipment.

The design of FIBC lifting loops is crucial; they must be strong enough to support the weight of the contents while ensuring stability during transport. Properly constructed lifting loops prevent accidents and injuries, making them a vital aspect of FIBC bag functionality.

Additionally, the configuration of these loops can vary, affecting how the bag is lifted and the distribution of weight. This ensures that the bag’s integrity is maintained throughout the lifting and transportation process.

Popular FIBC Bag Lifting Loop Options

Cross-Corner Loops

Cross-corner loops are one of the most widely used lifting loop designs in FIBC bags. These loops are attached diagonally across the corners of the bag, which helps to distribute the weight evenly. This design enhances stability during lifting, making it ideal for heavy loads. Cross-corner loops are particularly beneficial when bags need to be lifted from various angles, as they allow for better maneuverability.

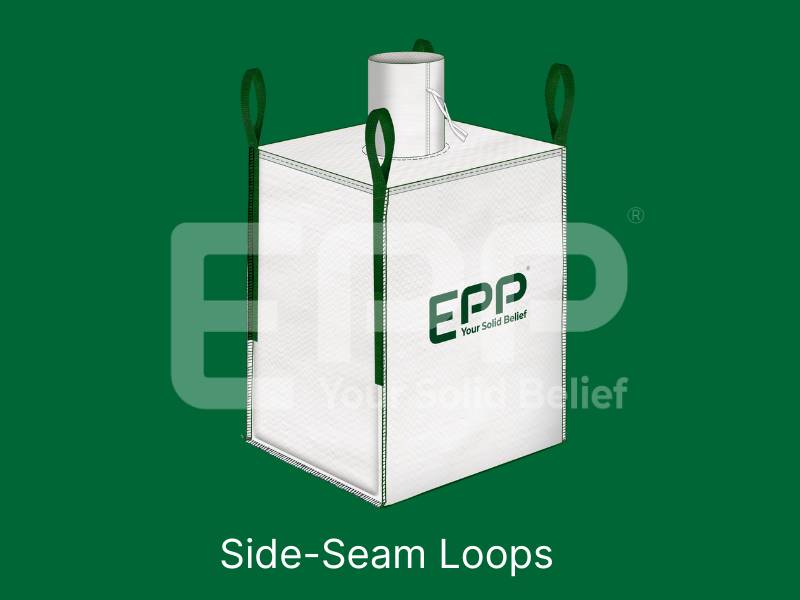

Side-Seam Loops (Corner Loops)

Side-seam loops, often referred to as corner loops, are another popular option. These loops are integrated into the side seams of the bag, offering a different lifting mechanism compared to cross-corner loops. Side-seam loops provide excellent strength and are less prone to tearing, making them a reliable choice for heavy-duty applications. However, they may not offer the same level of maneuverability as cross-corner loops.

Single / Double Loops

Single and double loops are designed based on the specific lifting needs of the FIBC bag. Single loops are sufficient for lighter loads, whereas double loops provide additional strength and stability for heavier materials. The choice between single and double loops should be based on the weight of the contents and the lifting method used. For example, double loops can be advantageous when using cranes or hoists that require extra security.

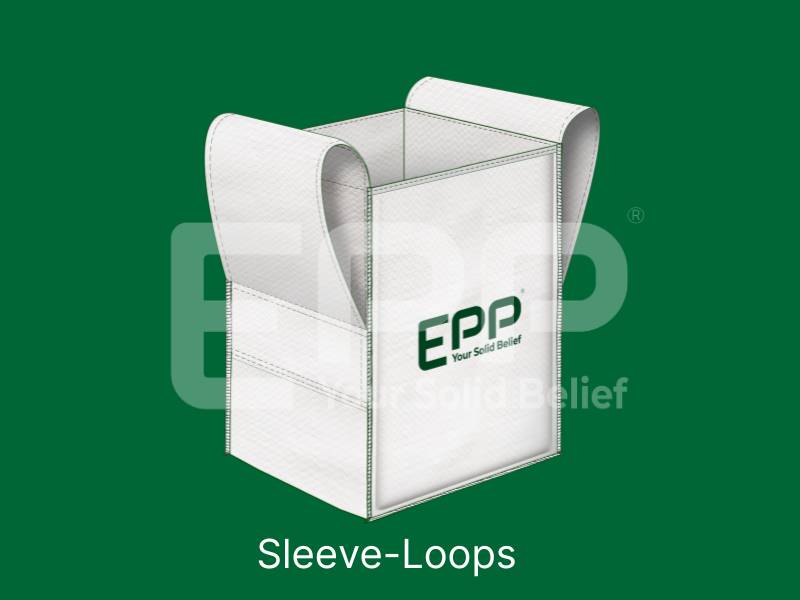

Sleeve Loops (Tunnel Loops)

Sleeve loops, also known as tunnel loops, are a more innovative option for FIBC bags. These loops are created by sewing a sleeve into the fabric, allowing for a more streamlined design. Sleeve loops can offer enhanced durability and flexibility, as they can be adjusted or replaced easily. This type of loop is particularly useful when bags need to be lifted frequently or when they are used in varying lifting conditions.

Stevedore Straps

Stevedore straps are specialized lifting loops that offer a robust solution for heavy-duty applications. These straps are typically wider and made from tougher materials, providing additional strength and support. Stevedore straps are often used in industries where bags are lifted frequently or where heavy materials are involved. Their design ensures minimal wear and tear, making them a reliable option for transporting bulk materials.

Choosing the Right Lifting Loop for FIBC Bags

When selecting the right lifting loop for FIBC bags, several factors should be considered:

- Load Weight: The weight of the materials being transported is a critical factor. Heavier loads require stronger lifting loops, such as double or cross-corner loops, to ensure safety during handling.

- Lifting Equipment: Consider the equipment that will be used for lifting. Some loops are designed for specific lifting methods, such as forklifts or cranes. Ensure that the chosen lifting loop is compatible with the equipment available.

- Type of Material: The type of material being stored or transported can influence the choice of lifting loop. For instance, abrasive materials may require more durable loops to withstand wear and tear.

- Usage Environment: Evaluate the environment in which the FIBC bags will be used. If bags are exposed to harsh conditions, such as extreme temperatures or moisture, selecting loops made from resistant materials is essential.

By carefully considering these factors, businesses can ensure they choose the right lifting loop that meets their operational requirements and enhances safety.

Loop Materials and Stitching Techniques

The materials and stitching techniques used in the construction of lifting loops play a crucial role in their performance and durability. Several common materials are utilized for this purpose.

Polypropylene is the most widely used material for lifting loops due to its strength, lightweight nature, and resistance to moisture and chemicals. Its excellent durability makes it suitable for a variety of applications.

Polyester loops are another option, known for their strength and resistance to UV light. They are particularly valuable in applications where exposure to sunlight is a concern, ensuring longevity in outdoor settings.

Nylon, while generally more expensive, offers superior strength and flexibility, making it ideal for heavy-duty applications. However, it may not provide the same level of UV resistance as polypropylene.

In terms of stitching techniques, several methods are employed to enhance loop durability. A single stitch technique involves a single line of stitching, making it appropriate for light-duty applications. However, this method may lack the strength needed for heavier loads.

For a more robust solution, double stitching reinforces the loop, significantly enhancing its strength and durability. This technique is commonly used for bags with double loops. For heavy-duty applications, reinforced stitching techniques, such as bar tacking, are applied to provide additional strength at stress points. Choosing the right materials and stitching techniques is essential for ensuring that lifting loops can safely and effectively handle the expected loads.

FAQ

What are FIBC bags?

FIBC bags, or flexible intermediate bulk containers, are large bags designed for transporting and storing bulk materials. They are commonly used in various industries, including agriculture, construction, and manufacturing.

What are super sacks?

Super sacks are another term for FIBC bags, typically used in the agricultural and industrial sectors. They are designed to hold large quantities of materials, making them ideal for bulk storage and transportation.

How much weight can FIBC bags lift?

The weight capacity of FIBC bags varies based on their design and construction. Most FIBC bags can safely handle loads ranging from 500 to 2,000 kilograms (approximately 1,100 to 4,400 pounds).

Are lifting loops removable?

Lifting loops are generally integral to the design of FIBC bags and are not meant to be removed. Removing them would compromise the bag’s integrity and safety during handling.

Conclusion

Understanding the importance of lifting loops in FIBC bags is crucial for ensuring safe and efficient handling of bulk materials. With various options available, including single, double, cross-corner, and sleeve loops, businesses can select the best option based on their specific needs. Additionally, considering materials and stitching techniques can enhance the performance and durability of lifting loops.

If you are looking for high-quality FIBC bags that feature robust lifting loops and meet your operational needs, contact EPP Vietnam. Our products are designed to provide durability and safety, ensuring your bulk materials are handled efficiently and securely. Let EPP Vietnam help you optimize your logistics and storage solutions today!