Static protective FIBC liners are essential components in the bulk packaging industry, designed to enhance safety and efficiency. These liners play a crucial role in protecting sensitive materials from the risks associated with static electricity, thereby ensuring safe handling and transportation. In this article, we will explore the characteristics, importance, classification, and best practices for using static protective FIBC liners, ultimately guiding you to make informed decisions for your business needs.

What are Static Protective FIBC Liners?

Static protective FIBC liners are specialized liners used within flexible intermediate bulk containers (FIBCs), commonly known as bulk bags, super sacks, or jumbo bags. These liners are designed to minimize the risk of electrostatic discharge (ESD) by dissipating static electricity, which can be particularly hazardous when handling flammable or sensitive materials. Made from conductive or anti-static materials, these liners protect the contents while maintaining the integrity of the packaging.

Importance of Static Protection

The importance of static protection cannot be overstated, especially in industries that handle combustible materials. Static electricity can build up during the filling, transportation, and discharging processes, leading to potentially dangerous situations, including fires or explosions. By incorporating static protective liners into your bulk bags, you significantly reduce the risk of ESD, ensuring a safer working environment for employees and safeguarding the products being transported.

Moreover, static protective liners enhance operational efficiency. By preventing static build-up, these liners ensure smoother material flow and reduce the likelihood of product contamination. This leads to decreased downtime and more streamlined processes, ultimately benefiting your bottom line.

Classification of Static Protective FIBC Liners

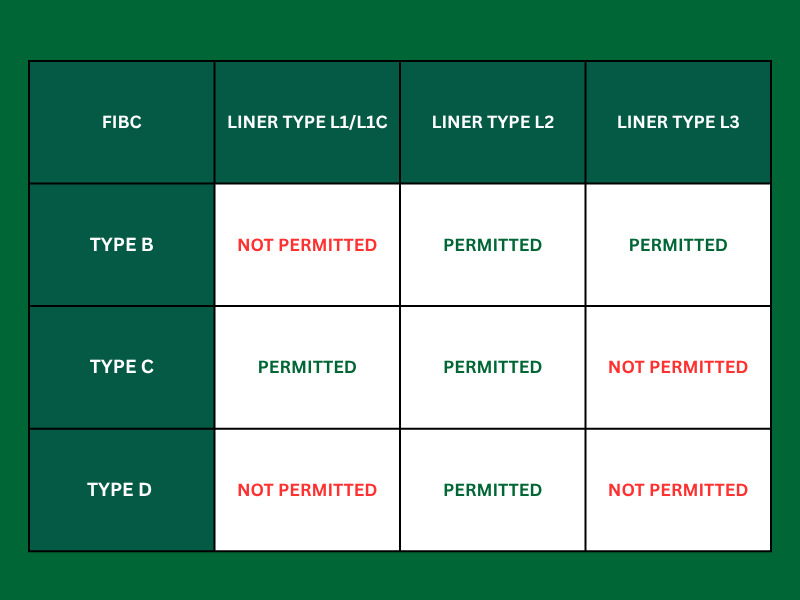

Static protective FIBC liners are categorized into three primary types as outlined in the International Standard IEC 61340-4-4. These classifications ensure safe handling and transportation of materials sensitive to electrostatic discharge (ESD).

Type L1 Liners

Type L1 liners are specifically designed for use in Type C FIBCs. These liners have a resistivity of less than 10^8 ohms on one or both surfaces. In the third edition of IEC 61340-4-4, a new configuration for Type L1 liners was introduced: the Type L1C liner, which is made from a multi-layer laminate featuring a conductive internal layer, typically aluminum.

A critical safety requirement for both Type L1 and L1C liners is that the conductive layer must be electrically bonded to the grounding system of the Type C FIBC, ensuring a secure connection to ground. This connection must be robust enough to withstand the rigors of filling, transport, and emptying. If the electrical connection fails, the liner can become an isolated conductor, posing a significant explosion risk due to electrostatic discharge.

Type L2 Liners

Type L2 liners serve as versatile static protective options, suitable for use in Type B, Type C, and Type D FIBCs. There are several permissible configurations for Type L2 liners, allowing for flexibility in application. Notably, when Type L2 liners are used in Type D FIBCs, the combination must pass ignition testing to ensure safety.

Type L3 Liners

Type L3 liners are exclusively permitted in Type B FIBCs. These liners are constructed from insulating materials but must maintain a breakdown voltage of less than 4 kV to prevent propagating brush discharges, ensuring that they do not initiate static-related hazards.

Additional Safety Considerations

It is crucial to note that conductive materials, such as aluminum, must not be incorporated into Type L2 or L3 liners. Using conductive materials in liners for non-grounded bulk bags, like Type B and Type D FIBCs, creates a risk of hazardous electrostatic discharge.

Furthermore, the inclusion of a liner must not alter the type classification of the FIBC. For instance, adding a Type L2 liner to a Type B FIBC does not change its classification, meaning it remains subject to the safety requirements and restrictions applicable to Type B FIBCs.

Choosing the Right Static Protective FIBC Liner

When selecting a static protective FIBC liner, it is essential to consider several key factors to ensure optimal performance and safety.

First and foremost is material compatibility. It is crucial to ensure that the liner material is compatible with the contents of the bulk bag. Different materials can react in various ways, so referring to product specifications is vital to avoid any adverse reactions.

Next, you should assess the static control requirements. Depending on the level of static risk associated with your materials, you will need to determine whether a conductive or anti-static liner is appropriate. This decision is crucial for ensuring safe handling and transportation.

The size and fit of the liner are also important factors. A liner should fit snugly within the FIBC bag to prevent movement during handling. Accurately measuring the dimensions of your bulk bags will help ensure a proper fit, which is essential for optimal performance.

Lastly, it is important to verify regulatory compliance. Check that the liner meets industry standards and regulations, particularly in sensitive sectors such as pharmaceuticals or food processing, where safety is paramount.

Static Protective FIBC Liners for Each Application

Static protective FIBC liners are versatile and can be adapted for various applications across multiple industries:

- Chemical Industry: In this sector, static protective liners made from conductive materials are essential for safely transporting flammable chemicals. They prevent static build-up, mitigating the risk of explosions.

- Pharmaceutical Industry: Anti-static liners that are also barrier liners are often used to protect sensitive pharmaceutical products from moisture and ESD, ensuring product integrity.

- Food Industry: Food-grade static protective liners are crucial for bulk storage and transport of food ingredients. They help maintain product quality while preventing contamination from static.

- Agricultural Products: For agricultural applications, static protective liners are used in FIBC bags to transport seeds and fertilizers, protecting them from static-related issues during handling.

By tailoring the choice of static protective FIBC liners to specific applications, businesses can enhance safety and ensure the quality of their products.

Common Problems and Solutions When Using FIBC Liners

While static protective FIBC liners are highly effective, users may encounter several common challenges that can impact their performance and safety.

One significant issue is static build-up. If this occurs despite using protective liners, it may indicate improper material selection. It is essential to ensure that the chosen liner is suitable for the specific materials being handled to mitigate this risk effectively.

Another challenge is liner damage, which can happen during handling or transit. To address this, it is crucial to train staff in proper handling techniques and conduct regular inspections of the liners for signs of wear and tear. This proactive approach can help identify potential issues before they escalate.

Incompatibility issues may also arise if the liner does not align with the FIBC bag or the materials inside. Always verify compatibility before use to prevent complications that could hinder operational efficiency and safety.

Additionally, moisture contamination can compromise product quality if moisture penetrates the liner. For sensitive materials, consider using barrier liners that provide extra protection against moisture, thereby safeguarding the integrity of the contents.

By proactively addressing these common challenges, businesses can maximize the effectiveness of their static protective FIBC liners and ensure safe operations.

Conclusion

Maximizing efficiency and safety with static protective FIBC liners is crucial for businesses handling sensitive or hazardous materials. By understanding the importance of static protection, selecting the right liner, and implementing best practices, companies can significantly reduce risks and enhance operational efficiency.

For the best static protective FIBC liners tailored to your specific needs, consider contacting EPP Vietnam. Our commitment to quality and expertise in the field ensures that you receive the most effective solutions for your bulk packaging requirements. Let us help you enhance safety and efficiency in your operations today!