If you handle bulk materials—from fine chemicals and fertilizers to sand and grains—you rely on Super Sacks (officially, Flexible Intermediate Bulk Containers or FIBCs). These industrial bags are designed for heavy lifting, but the question remains: Exactly how much weight and volume can they handle?

The short answer is: Super Sacks typically hold between 500 and 4,000 pounds, with the standard “1-ton” size safely holding 2,205 pounds. Capacity is a balancing act determined by the bag’s design, dimensions, and the density of your material. Getting the specifications right isn’t just about efficiency—it’s about safety. This guide breaks down the weight limits and volume capacities you need to know.

What are Super Sacks?

Super sacks, officially known as Flexible Intermediate Bulk Containers (FIBCs), are the workhorses of the industrial packaging world. These large, industrial-strength woven bags are designed to store and transport massive quantities of dry, flowable products—from sand and cement to grains and plastic pellets.

While they may look like gigantic shopping bags, they are engineered for heavy lifting, making them an essential, cost-effective, and surprisingly versatile solution for almost any bulk material handling challenge.

Detailed Breakdown of Super Sack Weight Capacities

The amount a super sack can safely hold (its Safe Working Load or SWL) is highly variable, depending on the bag’s size, its specific design (e.g., stitching, loop strength), and critically, the density of the material being filled.

Typical Capacities and Uses

The most widely used benchmark is the “1-ton” capacity , designed to safely hold one metric ton. Here is a breakdown of common capacity sizes:

| Capacity (lbs) | Standard Designation | Common Application |

| 500 | Lightweight | Often used for resins and low-density powders. |

| 1,000 | Half-Ton | Common for grains, flour, and food products. |

| 2,000 | One-Ton | Used for industrial chemicals and fertilizers. |

| 2,205 | The “1-Ton” Standard | The most frequently used size, safely holding one metric ton. |

Heavy-Duty and Custom Capacity Limits

For high-density materials (like certain ores or fine aggregates) or specialized industrial needs, reinforced super sacks are required:

- Common Heavy-Duty Capacity: These sacks are commonly rated to hold 4,000 pounds or more.

- Maximum Custom Capacity: Depending on specialized construction, reinforced seams, and custom lift loops, some super sacks can be manufactured to hold a maximum of 12,000 pounds (6 tons).

Super Sack Volume Explained

Weight capacity tells you the bag’s strength, but volume tells you how much space the material takes up. Super sack volume is measured in cubic feet (ft3) or cubic yards (yd3).

Volume varies significantly based on the bag’s dimensions (length, width, and height), but here are some common examples:

| Dimensions (L” × W” × H”) | Approximate Volume (cu ft) | Cubic Yard Equivalent (1 yd3=27 ft3) |

| 35″x35″x30″ | ~ 25 | Less than 1 |

| 35″x35″x42″ | ~ 81 | ~3 |

| 40″x40″x48″ | ~108 | ~4 |

| 48″x48″x48″ | ~122 | ~4.5 |

How to Find the Exact Volume?

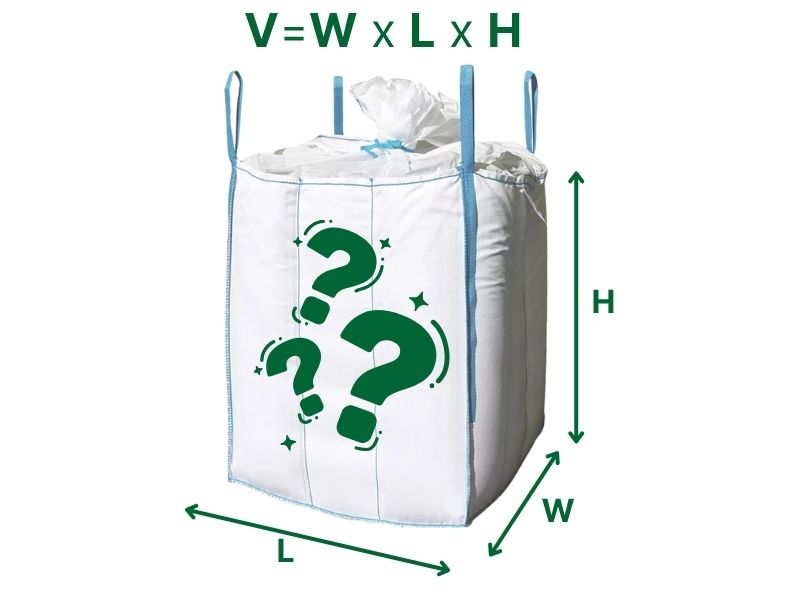

To ensure safety and efficiency, determining the precise volume you need is crucial. The formula is simple, but the best approach depends on your situation:

- Check Product Specifications: The most accurate and reliable method is to consult the manufacturer’s product sheet, which will explicitly list the volume in cubic feet or cubic yards.

- Calculate Using Dimensions: If you know the interior dimensions of the bag when it is filled (Length X Width X Height), you can calculate the volume yourself.

- Use the Standard Conversion: If you are comparing cubic feet to cubic yards, remember the quick conversion: 1 cubic yard is equal to 27 cubic feet.

FAQ about Super Sacks

What is the capacity of a supersack?

The typical, most common safe working capacity for standard industrial super sacks is 2,205 pounds (1 metric ton). The overall capacity range is 500 pounds, with specialized custom models going up to 12000 lbs.

How much sand does a supersack hold?

A standard 35″x35″x42″ super sack holds approximately 81 cubic feet, or 3 cubic yards of material. Because sand is dense, a bag this size would need to be a heavy-duty model to safely carry the total weight of 3 cubic yards of sand.

How much does a supersack full of sand weigh?

The weight depends on both the bag’s volume and the specific density of the sand. If you fill a standard 1 ton super sack (rated for 2,205 lbs) to its volume capacity, the final weight should not exceed that 2,205 lb limit, regardless of the material. The golden rule is never to exceed the bag’s Safe Working Load (SWL).

Are super sacks waterproof?

No, standard super sacks are woven polypropylene and are not inherently waterproof—they are slightly breathable. To protect contents from moisture, manufacturers offer bags with an internal polyethylene liner or laminated fabric, which makes them water-resistant or fully waterproof.

Conclusion

Super sacks are a robust and indispensable part of the logistics chain. Knowing how much material they can handle requires a clear understanding of two main factors: Weight Capacity (SWL), which speaks to the bag’s strength, and Volume Capacity, which speaks to the bag’s size.

The next time you’re sizing up a job, remember to match the density of your material to the bag’s specifications. A 48″x48″x48″ bag might offer 122 cubic feet of volume, but if you’re loading lead shot, you’ll hit that 2,205 lb weight limit long before the bag is full!