Woven PP bags, or polypropylene woven bags, are gaining popularity in various industries for their durability and versatility. As businesses and consumers seek effective packaging solutions, the debate between woven PP bags and jute bags continues. This article will explore both types of bags, comparing their features, benefits, and applications to determine which is the superior option.

What Are Woven PP Bags?

Woven PP bags are made from polypropylene, a thermoplastic polymer that is woven into a sturdy fabric. These bags are known for their strength, lightweight nature, and resistance to various environmental factors. PP woven bags are commonly used for packaging agricultural products, pet food, chemicals, and construction materials due to their excellent load-bearing capabilities.

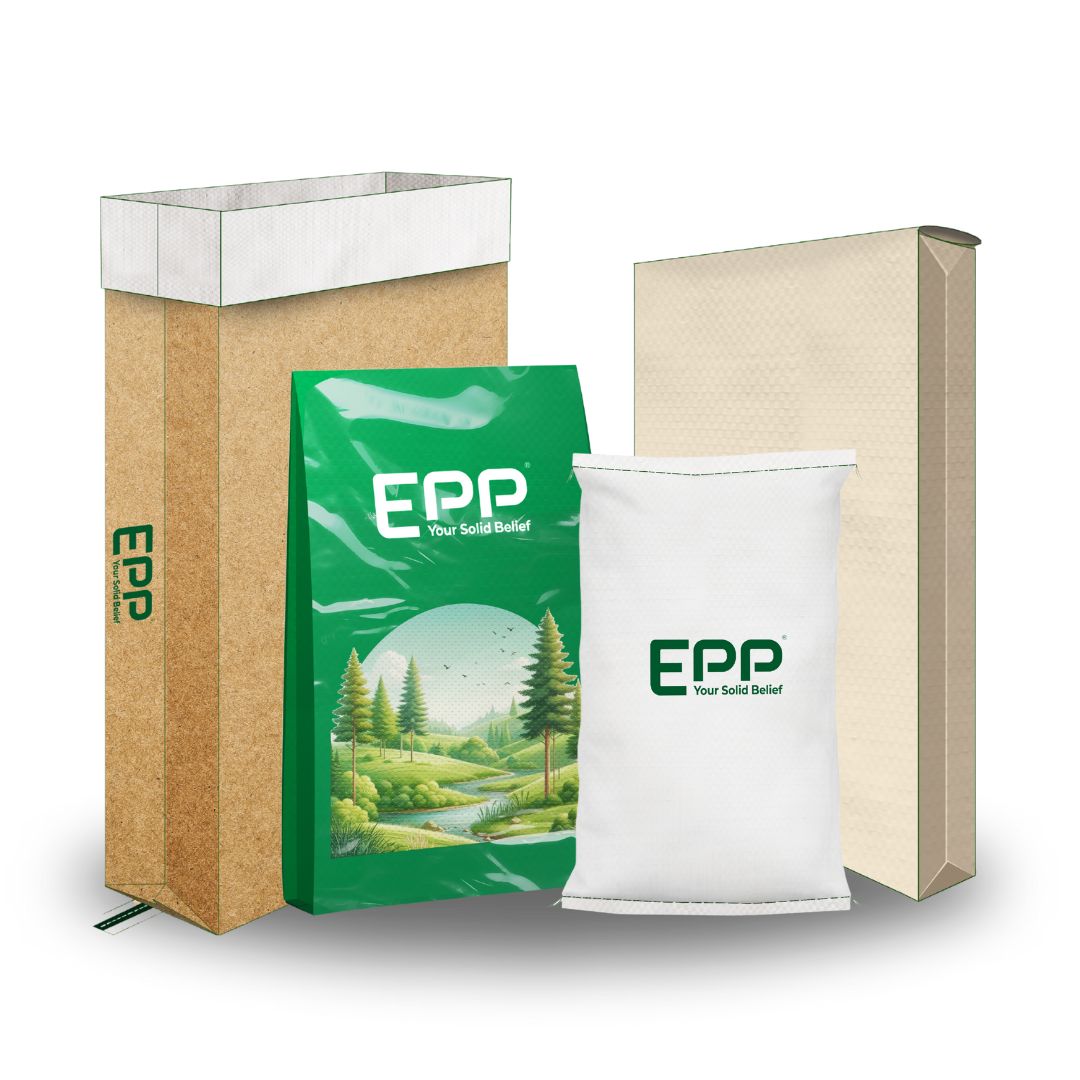

Manufactured through a process of weaving polypropylene fibers, these bags offer significant advantages over traditional packaging materials. They can be produced in various sizes, colors, and designs, making them highly customizable for branding purposes. Furthermore, woven PP bags can also be laminated with Kraft paper or other materials to enhance their barrier properties.

What Are Jute Bags?

Jute bags are made from the fibers of the jute plant, a natural and biodegradable material. Known for their rustic appearance and eco-friendliness, jute bags have been used for centuries as an alternative to plastic. They are often preferred for shopping, promotional items, and eco-conscious packaging solutions.

Jute bags are not only biodegradable but also recyclable, making them an attractive option for environmentally aware consumers. However, they do have limitations, particularly regarding durability and moisture resistance. While jute bags are strong, they can be susceptible to wear and tear over time, especially in wet conditions.

Woven PP Bags vs. Jute Bags

When comparing woven PP bags to jute bags, several factors come into play. Each type of bag has its unique strengths and weaknesses, which can influence the choice depending on the specific application.

Durability & Load Capacity

PP woven bags are generally more durable than jute bags. They can withstand heavy loads without tearing or breaking, making them suitable for packaging bulk products. Their woven structure provides added strength, allowing them to carry weights of up to 50 kg or more, depending on the bag’s specifications.

In contrast, while jute bags are strong, they may not handle heavy loads as effectively as woven PP bags. Jute fibers can fray and weaken over time, especially if subjected to moisture or rough handling. Therefore, for applications requiring high load capacity, woven PP bags are often the better choice.

Moisture & Weather Resistance

One of the significant advantages of woven polypropylene bags is their moisture resistance. Polypropylene is inherently resistant to water, which means woven PP bags can protect their contents from damp conditions and spills. This feature is particularly beneficial for agricultural products and chemicals that need to stay dry.

Jute bags, on the other hand, are less effective in wet conditions. While they can be treated to some extent for moisture resistance, prolonged exposure to water can lead to degradation and mold growth. Consequently, for outdoor or moisture-prone environments, woven PP bags are the more suitable option.

Cost & Production Efficiency

When it comes to cost, woven PP bags typically have an edge over jute bags. The production process for polypropylene woven bags is more efficient, allowing for mass production at a lower cost. As a result, they are often more affordable for businesses looking to minimize packaging expenses.

Jute bags, while eco-friendly, tend to be more expensive due to the labor-intensive process of harvesting and processing jute fibers. Additionally, the availability of raw materials can affect jute bag pricing, making them less accessible for some industries.

Environmental Impact

Both woven PP bags and jute bags have environmental considerations. Jute bags are biodegradable and made from a renewable resource, which makes them a sustainable choice for eco-conscious consumers. They also have a lower carbon footprint during production compared to synthetic materials.

PP woven bags, while recyclable, are made from plastic, which raises concerns about environmental pollution and waste. However, advancements in recycling technology are improving the sustainability of polypropylene. Many manufacturers are working towards creating recyclable and biodegradable versions of woven PP bags to address these concerns.

Customization & Branding

Woven PP bags offer extensive customization options, making them ideal for branding purposes. Businesses can easily print logos, designs, and colors directly onto the bags, allowing for effective marketing and product differentiation. This feature is especially valuable in competitive markets where branding plays a crucial role.

Jute bags also allow for some level of customization but are generally limited compared to woven polypropylene bags. The natural texture of jute can provide a unique aesthetic, but it may not support vibrant colors or intricate designs as effectively as polypropylene.

Industry Applications & Suitability

Both woven PP bags and jute bags find applications across various industries. Woven PP bags are commonly used in agriculture, construction, and food packaging, where durability and load capacity are paramount. They are ideal for transporting grains, fertilizers, and pet food.

Jute bags, on the other hand, are popular in retail, eco-friendly packaging, and promotional items. They are often favored for shopping bags and gift packaging due to their attractive appearance and biodegradability.

Market Trends & Consumer Preferences

As consumer preferences shift towards sustainability, both woven PP bags and jute bags are experiencing varying levels of demand. Jute bags are increasingly popular among environmentally conscious consumers who prioritize biodegradable products. Meanwhile, woven polypropylene bags are gaining traction due to their durability and affordability, appealing to businesses looking for cost-effective packaging solutions.

The market trends indicate a growing interest in recyclable and sustainable materials, prompting manufacturers to innovate within both categories. As a result, hybrid options that combine the strengths of both materials may also emerge.

FAQs

Are woven PP bags recyclable?

Yes, woven PP bags are recyclable. Many recycling facilities accept them, and advancements in recycling technology are improving their sustainability.

Can jute bags be waterproofed?

Yes, jute bags can be treated to enhance their moisture resistance. However, this treatment may not make them entirely waterproof, and prolonged exposure to water can still damage them.

Which bag is better for long-term storage?

For long-term storage, woven polypropylene bags are generally better due to their moisture resistance and durability. Jute bags may degrade over time, especially in humid conditions.

Are woven PP bags safe for food products?

Yes, woven PP bags are safe for food products, provided they are manufactured according to food safety standards. Look for bags specifically labeled for food use to ensure safety.

Conclusion

In the debate between woven PP bags and jute bags, each has its advantages and disadvantages. Woven PP bags offer superior durability, moisture resistance, and customization options, making them ideal for a wide range of applications. Jute bags, while eco-friendly and attractive, may not perform as well under certain conditions.

If you’re looking for high-quality PP woven bags for your business, consider contacting EPP Vietnam. Our products are designed to meet the diverse needs of various industries, ensuring durability, efficiency, and effective branding. Let EPP Vietnam help you find the perfect packaging solution today!