FIBC bulk bags are essential for storing fine powders, which are often highly susceptible to external environmental factors. Proper packaging and storage of fine powders such as flour, cement, or chemical powder are crucial to prevent damage. In this article, EPP aims to provide insights into the types of FIBC bulk bags that are ideal for storing fine powders. If you’re interested in finding the most suitable option for your needs, please read on!

The increasing demand for fine powder packaging

In addition to the storage function, the powder packaging also has the function of supporting convenient transportation, ensuring the safety of goods, providing information, and effectively advertising the brand. As a result, FIBC bulk bags for fine powder must have their own outstanding characteristics. However, not all types of packaging on the market can have the necessary features.

It can be said that packaging is the bridge between businesses and customers. Investing in packaging is an urgent solution that businesses cannot ignore. Starch such as wheat flour, tapioca flour and chemical powder should be stored in dry, completely moisture-proof conditions to avoid loss of quality. Therefore, companies producing fine powder often use jumbo packaging that are mechanically durable, waterproof, moisture-proof, and tear-resistant during transportation and impact.

What kind of FIBC bulk bags can store fine powder?

Jumbo bags for powder have working loads ranging from 500kg – 2000kg. Super sacks wholesale is intended primarily for preservation, distribution, and ease of use. Fine powder must be packed and transported in hygienic packaging to ensure the nutritional and technical quality of the product.

Packaging is only made of materials that are safe and suitable for intended use. The fibc bags must not release harmful substances or odors into the product. Most FIBC bulk bags are used to store products in powder or superfine powder form. Therefore, for large or super-fine powder products (such as flour, chemical powder, cement, etc.), it is necessary to design a specific big bag with high technical requirements. The big bag for fine powder needs to be leak-proof and not allow the product in the bag to be exposed to the external environment.

According to the manufacturer’s standards, big bags for flour will be manufactured according to a safety factor of 5:1 to ensure safety for one use. In addition, if the customer uses a jumbo bag for storing starch, the bag will be manufactured with a safety factor of 6:1 and reused many times.

1. Coated FIBC bags with Sift-Proof Seams

This is the baseline requirement for nearly all fine, flowable powders like cement, sugar, or fine sand.

-

Structure: A standard 4-panel or U-panel bag made from woven polypropylene.

-

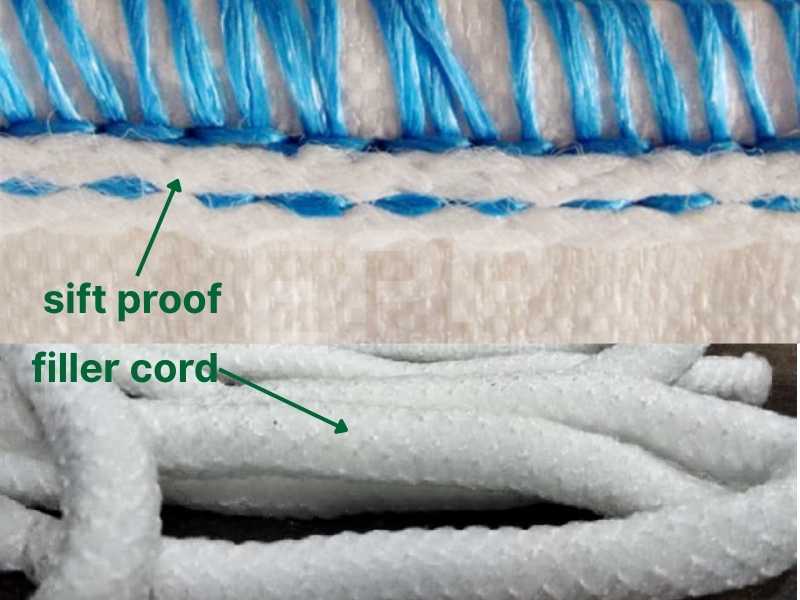

Key Feature: The fabric is coated/laminated with a thin layer of PP to seal the micro-gaps inherent in the woven material, providing basic moisture protection. Crucially, the seams are treated with felt or soft filler cord sewn into the stitching line. This cord expands under pressure, blocking any powder from escaping through the needle holes.

-

Best For: Products that are dusty but not highly prone to aeration.

2. Baffle Bag (Q-Bag) with Sift-Proof Seams

A baffle fibc bag is considered as a solution to keep the original shape of the bag. Products packed in this type of bag are also easy for transportation to different places without worrying about breaking or swelling. The baffle is made from woven, thin and coated PP fabric to connect the square corners of the bag.

The body of the Q bag is coated with a moisture-proof layer, depending on the volume of goods to be loaded. The top can have a filling skirt or filling spout. The bottom of the FIBC Bulk Bags has a discharge bottom or a closed bottom. The strap includes 4 straps at 4 fixed corners, customers can require 2 more belts for lifting the bag by crane.

-

Structure: Has internal fabric panels (baffles) sewn to the corners, forcing the bag to hold a square or rectangular shape after filling.

-

Key Feature: The square shape prevents the bulging that makes standard bags unstable and wastes container space. For powders, this design must be combined with the sift-proof seam technology mentioned above.

-

Best For: High-volume, high-density powders (like cement or powdered minerals) where shipping efficiency and stable stacking are paramount.

3. FIBC with Polyethylene Liner

This design is necessary when the fine powder is also highly hygroscopic (moisture-absorbing), such as specialty chemicals, flour, or certain fertilizers.

-

Structure: A standard outer woven PP bag containing a separate, sealed inner bag (liner) made of polyethylene (PE).

-

Key Feature: The inner liner acts as a primary, fully sealed barrier against moisture, oxygen, and pests, while the outer FIBC bags provides the structural support. Liners are often secured by gluing, tabs, or sewing them to the spout sections.

-

Best For: Food-grade powders (flour, starch, sugar) and materials sensitive to environmental conditions (chemicals, specialized pigments).

4. Anti-Static Bag (Type C or Type D)

When fine powders are filled or discharged, friction generates static electricity. If the powder is combustible (like flour, certain chemicals, or finely ground coal), a single static spark can cause an explosion.

-

Structure: The fabric contains interwoven conductive threads or is made entirely from antistatic material.

-

Type C: Conductive FIBC Bulk Bags that must be grounded during filling/discharging.

-

Type D: Dissipative bag that safely dissipates the charge without needing grounding (though it requires a specialized conductive coating).

-

-

Key Feature: Prevents sparks, fulfilling critical safety compliance requirements.

-

Best For: Any combustible or explosive fine powder.

You have read the article sharing about What kind of FIBC bulk bags can store fine powder and the quality product supplier. If you want to buy cheap and quality fibc super sacks, please visit https://epp.vn to see the model or contact +84 986.002.888 now for a detailed quote. In an era with many models and premium Jumbo bags on the market, finding a quality supplier for this product line can be a big challenge. However, EPP Vietnam will give you the best solution to this dilemma when exporting fine powder.