UN-certified bulk bags —also known as UN-rated bulk bags or UN FIBC bags—are essential packaging solutions for transporting hazardous materials safely and in compliance with international regulations. These specialized containers are designed to withstand the rigors of handling, storage, and transport across various industries, including chemicals, agriculture, pharmaceuticals, and mining. To ensure their reliability, UN bags must undergo a series of standardized testing methods that simulate real-world conditions and verify their structural integrity and containment capabilities.

What Are UN-Certified Bulk Bags?

UN-certified bulk bags are a type of Flexible Intermediate Bulk Container (FIBC) that meets the stringent standards set by the United Nations for the transport of dangerous goods. These bags are constructed from woven polypropylene and are engineered to carry solid hazardous materials in bulk quantities. Unlike standard FIBCs, UN-rated bulk bags are tested and certified to ensure they can safely contain and transport materials classified under Packaging Groups I (high danger), II (medium danger), and III (low danger).

UN approved fibc bags are marked with a unique UN certification code that indicates its compliance with international transport regulations such as ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road), IMDG (International Maritime Dangerous Goods Code), and DOT (U.S. Department of Transportation). These markings help users identify the bag’s suitability for specific hazardous materials and transport conditions.

Why Testing UN-Certified Bulk Bags Is Crucial?

Transporting hazardous materials without proper packaging can lead to serious consequences, including environmental contamination, injury, and regulatory penalties. That’s why standardized testing is a critical component of the UN certification process. These tests ensure that UN-certified bulk bags can endure the physical stresses of lifting, stacking, vibration, and accidental drops without compromising their structural integrity or containment.

Testing also provides assurance to manufacturers, logistics providers, and regulatory agencies that the packaging meets global safety standards. By using UN-certified bulk bags, businesses can reduce liability, enhance safety, and ensure compliance with international transport laws.

Overview of Standardized Testing Methods

To earn UN certification, bulk bags must pass a series of rigorous tests that evaluate their performance under simulated transport and handling conditions. Each test is designed to assess a specific aspect of the bag’s durability and containment capabilities—such as lifting strength, resistance to tearing, and stability under pressure.

These tests must be conducted by accredited laboratories that specialize in dangerous goods packaging. One of the most respected institutions in this field is Labordata, an internationally recognized materials testing institute for FIBCs. Labordata performs all required UN tests—including the top lift, drop, stack, topple, righting, and tear tests—with precision and full adherence to UN regulations. Their certification process is trusted by un certified fibc suppliers and regulatory bodies worldwide, making them a reliable partner for ensuring compliance and safety in hazardous goods transport.

Top Lift Test

Load Requirements:

This test evaluates the strength of the bag’s lifting loops and overall construction. The UN-rated bulk bag is filled to its maximum capacity and lifted using all loops.

Structural Integrity Checks:

To pass, the bag must withstand a load equal to six times its rated capacity for five minutes without tearing, loop failure, or structural deformation. This ensures the bag can be safely lifted by cranes or forklifts during handling.

Stack Test

Simulated Stacking Conditions:

Bulk bags are often stacked in warehouses or during transport. The stack test simulates the pressure exerted by stacking multiple un approved bulk bags on top of each other.

Duration and Pressure Standards:

A load equal to 1.8 times the weight of the stacked bags is applied to the test bag for 24 hours. The bag must not collapse, deform, or leak under this pressure.

Drop Test

Height Variations by Packaging Group:

The drop test assesses the bag’s ability to withstand accidental drops. The height from which the bag is dropped depends on its packaging group:

- Group I: 1.2 meters

- Group II: 0.9 meters

- Group III: 0.8 meters

Impact Resistance Expectations:

The UN Big bag is dropped onto a hard surface in multiple orientations—flat, on its side, and on its corner. It must not rupture or leak upon impact.

Topple Test

Stability Assessment:

This test simulates the bag tipping over during handling or transport. The UN bag is tilted and allowed to fall naturally.

Real-World Tipping Scenarios:

To pass, the bag must remain intact and retain its contents without any signs of damage or leakage. This test is especially important for tall or narrow bags that are more prone to tipping.

Righting Test

Purpose and Procedure:

The righting test evaluates the strength and flexibility of the lifting loops when the bag is repositioned. The UN FIBC bag is filled to its maximum Safe Working Load (SWL) and deliberately tipped onto its side. It is then returned to an upright position using only two of its lifting loops.

What Qualifies as a Pass:

To pass, the bag and its lift loops must remain undamaged, showing no signs of stress, tearing, or deformation. This test ensures the bag can be safely repositioned during handling without compromising its integrity.

Tear Test

Puncture Resistance:

The tear test evaluates the bag’s ability to resist cuts and punctures. A controlled incision is made in the bag’s surface to simulate damage from sharp objects.

Material Durability:

With the FIBC filled to its maximum SWL capacity, a controlled incision measuring at least 100 mm in length is made at a 45-degree angle. The bag is then subjected to a load equal to twice its SWL for a duration of five minutes. To pass, the tear must not propagate more than 25% beyond its original length, ensuring the material’s resistance to further damage under stress.

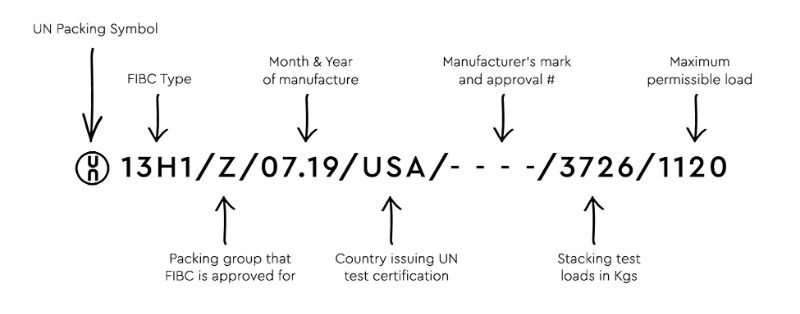

Certification Marking and What It Means

Once a bulk bag passes all required tests, it receives a UN certification mark. This mark includes a series of codes that provide detailed information about the bag’s specifications and approval status.

Breakdown of UN Marking Codes:

- UN Symbol: Indicates compliance with UN standards

- Packaging Code (e.g., 13H3, 13H4): Specifies the type of FIBC

- Packaging Group: I, II, or III

- Country of Approval: Where the certification was issued

- Manufacturer Code: Identifies the producer

- Year of Manufacture: Ensures traceability

How to Verify a Certified Bulk Bag:

Always check the UN mark printed on the bag. It should be legible, complete, and match the documentation provided by the supplier. If in doubt, request a copy of the test report or certification document to confirm authenticity.

Choosing the Right UN-Certified Bulk Bags

Selecting the correct UN-Certified bulk bags depends on several factors:

- Type of hazardous material

- Required packaging group

- Transport method (road, sea, air)

- Storage conditions

Work with a trusted supplier who understands regulatory requirements and can provide documentation for each bag. Avoid generic or unmarked bags, as they may not meet compliance standards and could expose your business to legal and safety risks.

Conclusion

Standardized testing methods for UN-certified bulk bags are essential for ensuring the safe transport of hazardous materials. Each test—from righting and lifting to tearing and dropping—plays a vital role in verifying the bag’s durability, stability, and containment capabilities. By choosing bulk bags with un rating, businesses can protect their products, people, and reputation.

At EPP VIETNAM, we specialize in high-quality bulk packaging solutions that meet international standards. Whether you need UN-certified bulk bags, UN-rated FIBC bags, or durable standard big bags for industrial use, our team is here to help you find the right product for your needs.