Bulk bags, also known as Flexible Intermediate Bulk Containers (FIBCs), are a critical component in modern industrial packaging and logistics. These large, durable containers are designed to store and transport dry, flowable materials such as grains, powders, chemicals, and construction aggregates. Their versatility, cost-effectiveness, and adaptability have made them indispensable across a wide range of industries.

This article provides a comprehensive overview of bulk bags, including their composition, functionality, and global supply trends. Understanding these essential facts can help businesses make informed decisions when selecting packaging solutions for bulk materials.

What Are Bulk Bags?

Bulk bags are flexible containers constructed from woven polypropylene fabric. They are engineered to carry substantial quantities of material—typically ranging from 500 kilograms to 2,000 kilograms—and are equipped with lifting loops for easy handling via forklifts or cranes. Their intermediate size makes them ideal for bulk transport, bridging the gap between small sacks and rigid containers.

FIBCs are widely used in sectors such as agriculture, construction, chemicals, pharmaceuticals, and food processing. Their design allows for efficient storage, transport, and discharge of materials, contributing to streamlined operations and reduced packaging costs.

10 Essential Facts About Bulk Bags

1. Officially Known as FIBCs

While commonly referred to as bulk bags, the formal industry term is Flexible Intermediate Bulk Containers (FIBCs). This designation reflects their structural flexibility, intermediate capacity, and suitability for bulk handling. FIBCs are subject to international standards that govern their design, testing, and usage to ensure safety and reliability.

2. Constructed from Polypropylene

Bulk bags are manufactured using woven polypropylene, a thermoplastic polymer derived from petroleum. This material offers high tensile strength, chemical resistance, and lightweight properties, making it ideal for industrial packaging. Despite its petroleum origin, polypropylene is recyclable, contributing to the sustainability of bulk bag usage.

3. Available in Various Shapes and Sizes

Bulk bags are highly customizable to meet specific operational requirements. Standard dimensions are approximately 35 inches by 35 inches by 50 inches, although variations exist for different volumes and materials. Common configurations include U-panel bags, circular bags, and baffle bags.

4. Reusable and Recyclable

Many bulk bags are designed for multiple uses, particularly those with a Safety Factor (SF) of 6:1, indicating they can safely be reused up to six times their rated load. This reusability reduces waste and operational costs. Additionally, polypropylene’s recyclability supports environmental sustainability initiatives.

5. Rated for Safety: SWL and SF

Each bulk bag is assigned two critical safety ratings: Safe Working Load (SWL) and Safety Factor (SF). The SWL indicates the maximum weight the bag can safely carry, while the SF represents the ratio of the bag’s tested strength to its SWL

6. Not Waterproof by Default

Bulk bags are not inherently waterproof. To protect moisture-sensitive contents, manufacturers offer enhancements such as laminated coatings and polyethylene liners. These features are crucial for applications involving food-grade materials, pharmaceuticals, or chemicals requiring moisture protection.

7. Equipped with Lifting Loops

Bulk bags are designed for efficient handling through the use of lifting loops. Common loop configurations include:

- Corner loops: Standard for most applications

- Cross-corner loops: Facilitates easier forklift access

- Stevedore straps: Enables dual-point lifting

Proper loop design ensures safe and effective transport, especially in high-volume industrial settings.

8. Baffle Bags for Shape Retention

Baffle bags incorporate internal panels that help the bag retain a square shape when filled. This design improves stacking efficiency, reduces storage space requirements, and enhances stability during transport. Baffle bags are particularly useful in environments where space optimization is critical.

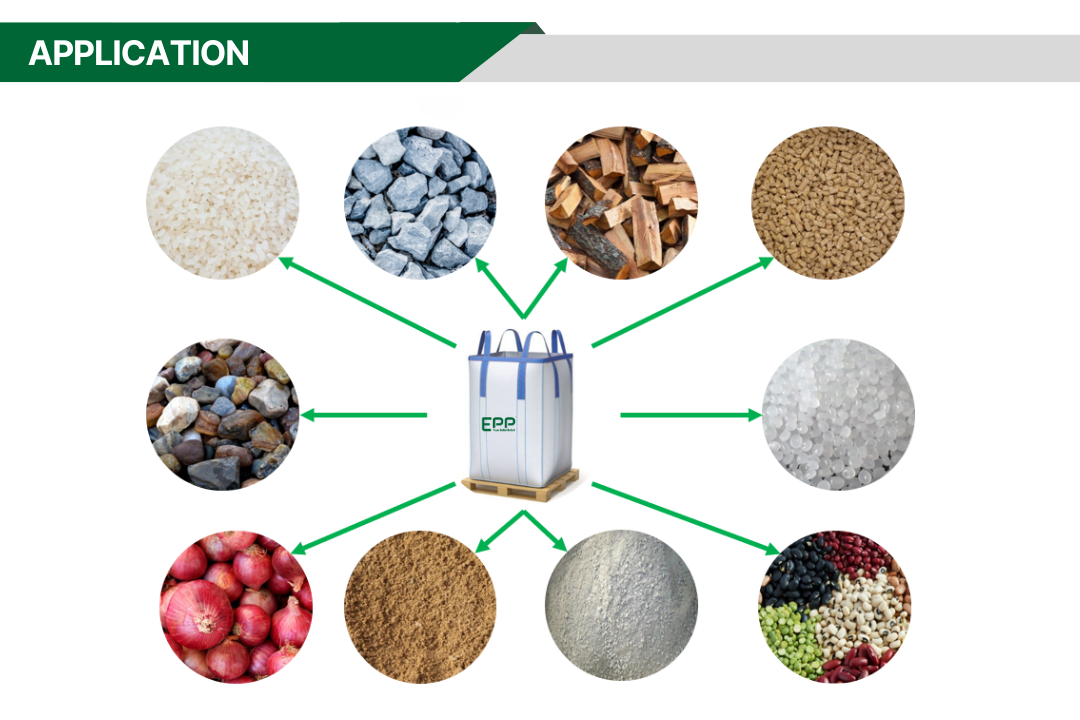

9. Utilized Across Diverse Industries

Bulk bags are employed in a wide array of industries due to their adaptability and strength. Common applications include:

- Agriculture: Transporting seeds, grains, and fertilizers

- Construction: Handling sand, gravel, and cement

- Chemicals: Storing powders and hazardous materials

- Food processing: Packaging sugar, flour, and salt

- Pharmaceuticals: Containing active ingredients and excipients

Their widespread use underscores their importance in global supply chains.

10. Highly Customizable

Bulk bags can be tailored to meet specific business needs with options such as printed branding, discharge spouts, UV protection, and color-coded loops for identification.

Emerging Bulk Bag Suppliers Around the World

As global supply chains continue to evolve, several countries are emerging as key players in bulk bag manufacturing. These nations offer competitive pricing, skilled labor, and growing industrial capabilities.

India

India remains a leading supplier of bulk bags due to its robust polypropylene production, cost-effective labor, and established export infrastructure. Indian manufacturers are known for producing high-quality FIBCs at scale.

Vietnam

Vietnam is gaining prominence as part of the “China Plus One” strategy, which encourages diversification of supply chains. The country offers modern manufacturing facilities, strategic geographic positioning, and increasing expertise in packaging solutions.

Indonesia

Indonesia’s expanding industrial base and participation in regional trade agreements make it an attractive source for bulk bags. The country is investing in polymer technology and packaging innovation to meet global demand.

Bangladesh

Bangladesh is leveraging its strong textile industry to enter the bulk bag market. With low labor costs and rising investment in polymer-based packaging, it is becoming a competitive supplier for international buyers.

Turkey

Turkey’s strategic location between Europe and Asia, combined with its advanced polymer industry, positions it as a valuable supplier of bulk bags. Turkish manufacturers offer high-quality products with efficient shipping to European markets.

Conclusion

Bulk bags are a vital component of industrial packaging, offering strength, flexibility, and cost-efficiency across a wide range of applications. Understanding their composition, safety ratings, and customization options enables businesses to optimize their logistics and storage operations.

As demand for bulk bags continues to grow, emerging supplier countries such as Vietnam, Indonesia, and Bangladesh are reshaping the global market with innovative and sustainable solutions. By staying informed about these developments, companies can make strategic sourcing decisions that enhance performance and reduce costs.

For organizations seeking reliable bulk bag solutions, partnering with experienced manufacturers and exploring new sourcing regions can provide a competitive edge in today’s dynamic industrial landscape.