U-panel FIBC bulk bags, also known as U-panel bags, are manufactured by using a long piece of PP fabric to create two sides and a bottom of the bag (forming a U shape). Then manufacturers will sew 2 more smaller pieces on the other 2 sides to form a complete bag. What are the features and structure of this type of bag? Let's find out the answer with EPP Vietnam right in this article.

Structure of U-panel FIBC bulk bags

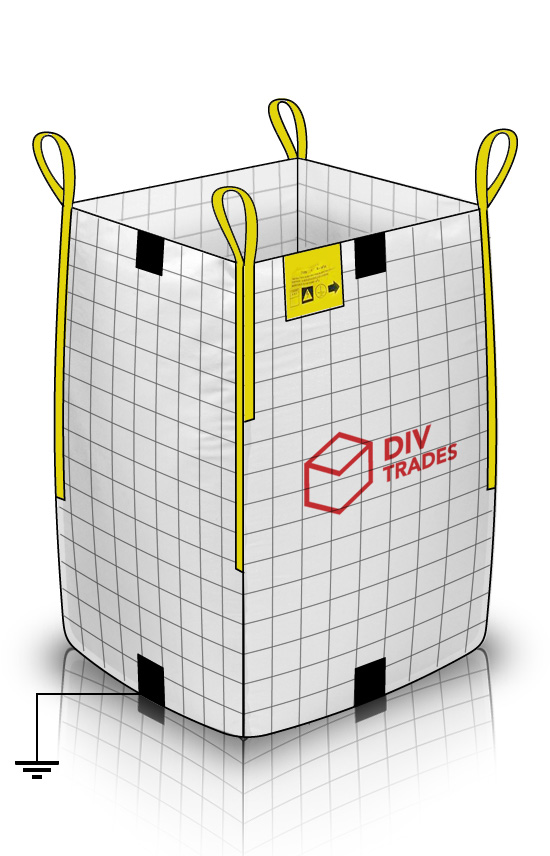

U-panel bags are manufactured by using a long piece to make two sides and the bottom then adding 2 more short pieces on the other sides.

U-panel FIBC bulk bags, also known as U-panel bags, are manufactured by using a long piece of PP fabric to create two sides and a bottom of the bag (forming a U shape

An U-panel jumbo bag is an industry standard design offering the benefits of sturdiness, stackability and cost-effectiveness.

Specification of U-panel FIBC bulk bags

– The Body: U-panel builder bags are made from coated or uncoated PP (polypropylene) fabric, weighing from 120g/m2 to 250g/m2 depending on their working load and the nature of contained products.

– The Top: According to the product and the filling device, U-panel bag’s top can be designed with a skirt cover, a filling spout, a 3-side open flap top or fully open top.

– The bottom: U-panel Jumbo bags can have a flat bottom (closed bottom), a discharge bottom with Iris closure or star closure .

– The loops: An U-Panel bag at EPP Vietnam are designed with 4 side seam loops, which can be attached with 2 more stevedore straps.

Advantages of U-panel Jumbo bags

U-panel big bags have the bottom and two sides of the same piece, so it can distribute the weight more evenly and increase the bag’s strength. This bag has a safety factor of 5:1 and reaches a normal working load from 500kg to over 2,000kg for continuous transportation of heavy materials.

U-panel big bags have the bottom and two sides of the same piece, so it can distribute the weight more evenly and increase the bag’s strength

Besides the U-panel bags, EPP also produced tubular jumbo bags which have seamless bodies. They are ideal for storing and transporting products that are often contained in packaging bags with a capacity of 2000kg. Tubular bulk bag is also suitable for storing materials without an inner liner.

Notes when using U-panel FIBC bulk bags

U-panel Jumbo bag is a specialized bag to preserve goods, raw materials, agricultural products, etc. With the characteristic of containing large loads of goods, it is advisable to move this filled bag mainly by forklift. To properly lift and unload Jumbo bags, you need to keep in mind some following information.

Before using, it is necessary to carefully read the label to understand the recommendations as well as important notes during the handling process.

– Bulka bags usually have 4 lifting loops at 4 corners to meet the lifting requirements, but these straps are easy to tear if not lifted properly.

– In case the forklift has a sharp fork that can damage the loops, you can use a round tube instead or inform the bulk bags manufacturers

to reinforce those with a stronger woven PP layer.

Readers have just referred to the article sharing about the specification and guidelines when using U-panel FIBC bulk bags. If you want to own quality jumbo bags at affordable prices, please visit https://epp.vn to choose some free samples and contact hotline + 84 986 002 888 for the most detailed advice.

🌐Website:https://epp.vn - https://eppvietnam.trustpass.alibaba.com

📲Ms. Jennifer: +84 962 055 998 - sales02@epp.vn

📲Ms. Charlie: +84 986 002 888 - sales@epp.vn