With over 16 years of experience as the leading company in the field of FIBC packaging production, EPP Vietnam Co., Ltd selects and uses modern technological lines imported from long - experienced companies in FIBC production such as Hana, Seijin - Korea; Lohia - India, Yongmin - China and a number of auxiliary equipment of India, Taiwan, China, Austria...

Our production lines include:

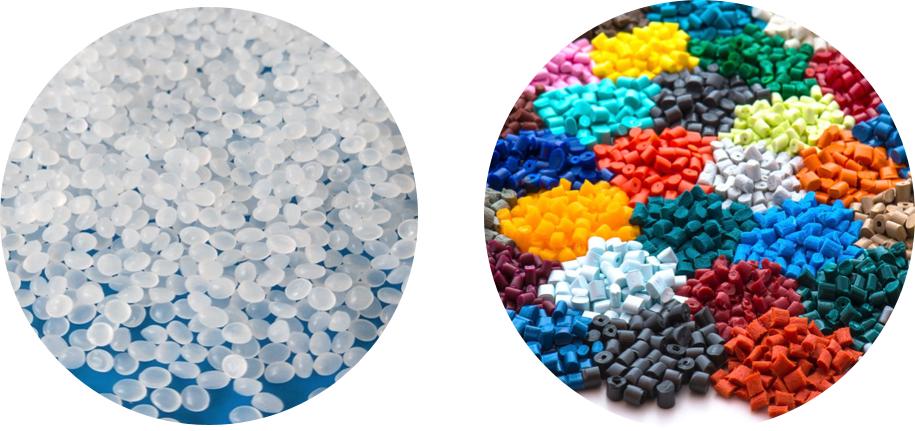

1. Raw material

Our main materials are polypropylene plastic resin, color resin, additive resin, UV resin … are imported according to manufacturer’s requests

2. Yarning process

Modern extrusion machine line creates the best yarn with high Denier.

3. Weaving fabric and loops

Circular loom machine can weave fabric with the width from 900mm to 2500mm, high fabric density. The fabric surface is tight and stable.

Weaving loop machine can create some kind of loops with width from 20mm to 110mm, high strength, good loading weight to use.

4. Lamination

Lamination machine can laminate fabric with the width from 900mm to 2500mm, lamination density 15-30gm2.

5. Cutting fabric

Cutting fabric machine, cutting loops machine and cutting accessories machine can cut product with different dimensions, according to manufacturers' request.

6. Flexo printing

Flexo printing machine 3 - 5 colors can print images on fabric clearly and exactly.

7. Sewing

Sewing machine system can meet all technological requirements for FIBCs such as single needle sewing, double line sewing, overlock,…

8. Inspection

Our QC team have a lot of experiences and strength tester machines with high accuracy to ensure the products’ quality.

9. Packaging

Baling press machine, which has various pressures, is suitable for packing with flexible quantity

10. Shipment

With professional transport service, we commit to delivery products safely, on time.

.jpg)

.jpg)

.jpg)

.png)