PP woven fabric is the finished product after the weaving process from polypropylene plastic yarn. This PP woven fabric does not stretch easily, therefore, it is very durable. As a result, it is often chosen to produce large super sacks such as jumbo bags thanks to the ability to withstand strong external forces.

However, when choosing PP woven fabric to produce fibc jumbo bags, what should you pay attention to? Please follow the article to know some notes when choosing PP woven fabric for big bags.

General information about PP woven fabrics

PP woven fabric or polypropylene fabric is a woven product derived from polypropylene polymer. This resin is part of the polyolefin group which is nonpolar and only partially crystalline. Polypropylene is the second most popular plastic in the world after polyethylene. They are commonly used in packaging, consumer products, and other industrial items.

Polypropylene's history of development

In 1951, polypropylene was first discovered in the United States by the oil company of Phillips Petroleum. Chemists Robert Banks and J. Paul Hogan accidentally created polypropylene while trying to make gasoline from propylene. They realized that this new compound (polypropylene) was just as valuable as polyethylene in many applications.

In 1954, Italian chemist Giulio Natta and his colleagues succeeded in forming this substance in polymer engineering. The Montecatini Company soon began to manufacture substances for commercial and consumer purposes. But it was not until 1957 that polypropylene was gradually developed, and made into a suitable substance for mass production and worldwide use.

Features of PP woven fabric

PP woven fabrics show potential use in the textile industry. Polypropylene fabric is made directly from the material without the need to rotate the weave. The main benefit is that it prevents absorbing any external moisture, instead, the moisture penetrates the PP fabric completely.

Polypropylene fabric is one of the lightest synthetic fibers in existence, it is extremely resistant to both acids and alkalis. In addition, the thermal conductivity of this PP fabric is much lower than that of most synthetic fibers which is suitable for cold weather.

The polypropylene fabric is very durable, fade-resistant, and inherently stain-resistant. This is because the construction of polypropylene will not work when dyed after it has been synthesized. This makes polypropylene woven fabrics ideal for textile applications.

Some notes when choosing PP woven fabric for FIBC jumbo bags

With the above advantages, PP fabric is widely used in many fields, especially agriculture, industry, construction, and chemicals. These can be mentioned as packaging, or bulk bags. For FIBC products with such a large load, what standards should the input material meet? Here are some notes when choosing PP woven fabric for jumbo bags.

Quantification of PP woven fabric for sewing FIBC jumbo bags

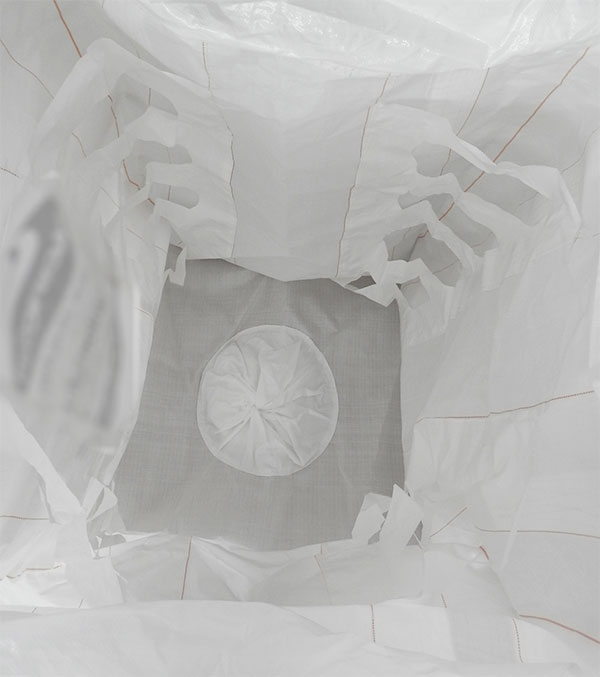

PP woven fabric will be cut and wrapped into a large roll of fabric. Therefore, when choosing materials to produce jumbo bags, manufacturers will choose the suitable one based on the fabric weight. The fabric for the top or bottom spout will have a completely different weight than the one for the body.

The fabric plays a decisive role in the mechanical properties of the packaging quality, which is calculated in units of g/m2. This quantification is the density and thickness of the plastic fabric. The fabric weight of the filling spout will range from 65 - 85 g/m2. On the contrary, the body of the bag will be selected with a weight of 120-250 g/m2.

Yarn density and fabric width

The yarn density and fabric width will be selected according to the number of yarns in an area greater or less than the standard density. Warp density is the number of yarns over 10cm along the fabric width and weft density is the number of yarns over 10cm along the fabric length.

At the same time, the optimum tensile strength should be as standard as 28.8Mpa. In addition, depending on the printing needs, packaging design, and sewing process, the fabric width is also carefully selected. Finally, depending on the type of goods being packed, the spouts and body of the FIBC jumbo bag are coated with PP film or not.

Recently, EPP VietNam has shared with readers information about the characteristics of polypropylene woven fabric as well as some notes when choosing PP woven fabric for FIBC jumbo bags. If you want to buy cheap and quality bulk bags, please visit https://epp.vn to refer to the model or contact +84 986.002.888 now for a detailed quote.

🌐Website:https://epp.vn - https://eppvietnam.trustpass.alibaba.com

📲Ms. Jennifer: +84 986 002 888 - sales@epp.vn

📲Ms. Vera: +84 962 055 998 - sales02@epp.vn

📲Ms. Ivy: +84 973 650 865 - sales03@epp.vn

📲 Mr. Lee: +84 976 791 865 - sales03@epp.vn