FIBC bags (bulk bags, jumbo bags, super sacks) are proven to be ideal for storing and transporting a variety of products. One customizable feature of jumbo bags that make them a versatile bulk packaging solution is the top loop construction. With various loop options, jumbo bags can be customized to fit your specific application and operation.

This article will help you explore the pros and cons the most common types of lifting loops used and determine which type of lift loops are right for your application.

Corner Seam Loops (Loop over Loop)

Corner seam lift loops can be found on U-Panel and 4-Panel bag constructions. Corner seam loops, also known as Loop over loop or side seam loops, are the most commonly type of loop construction. Corner seam lift loops are sewn along the side seams of the bag. The loop begins and ends at the same point on the bag forming a tear drop shape. The most common corner seam lift loop size is 2 inches in width x 10 inches in free height. U-Panel bags with corner seam loops are more costly than tubular bags. However, they are extremely strong and durable.

This type of bag can be lifted by a forklift, but all four loops must be used making loading and transporting bags somewhat of a difficult process.

Pros: Loop over loop/corner seam loops are the most common type of loop and are a cost effective option.

Cons: This type of loop construction may be harder to use with forklifts.

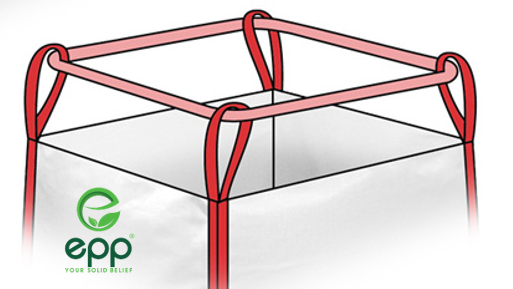

Cross Corner Loops

Cross Corner lift loops can be found on tubular or “circular” bag constructions. Much like loop over loop lift loops, cross-corner loop bags are constructed with loops in each corner of the bag . However, instead of the loops being sewn into the seam of the bag, they are sewn onto the body of the FIBC and form an “arch” over each corner. The most common cross corner lift loop size is 3 inches in width x 10 inches in free height.

These specific types of loops are designed to ensure that the lifting loops stand upright making it easier for forklift operators to grab and lift thus reducing bag handling times.

Pros: Cross corner loops stand upright making it easy for forklift operators to grab and lift

Cons: Usually more expensive than loop over loop construction

Stevedore Straps (Stevedore Lift Loops, Single, Double, & Supporting Loops)

Stevedore straps are an special supporting component to a cross corner or corner seam loops for safe handling of bulk bags. While bags with four loops must be lifted at all four points for safe handling, bags with Stevedore loops allow lifting equipment to lift from only one or two

Bulk bags used for export shipping and areas where traditional forklift access is difficult are oftentimes equipped with stevedore straps. The straps allow the operator to easily raise and lower a bag with a crane or hook system.

There are three different types of Stevedore Straps:

1. One Stevedore Loop: is a loop pulled through the four standard corner loops to connect all of them.

1. One Stevedore Loop: is a loop pulled through the four standard corner loops to connect all of them.

2. Double Stevedore Loops: are two loops that connect each parallel loop at the corners.

2. Double Stevedore Loops: are two loops that connect each parallel loop at the corners.

3. Supporting Stevedore Loops: are supporting loops that are attached to each corner loop.

3. Supporting Stevedore Loops: are supporting loops that are attached to each corner loop.

Pros: Ability to lift the bag by one or two loops. Multiple ways to lift bag.

Cons: Specialty and can be more expensive

Sleeve Loops/Lift Tunnel Loops

Sleeve/Lift tunnel loops are a special type of loop made from bulk bag body fabric. Sleeve/Tunnel loops are a very practical style of lift loop for operations exclusively using forklifts to pick up and move FIBCs. If you are using forklifts to move bulk bags, then bags with sleeve/tunnel lift loops are a great option for you. Sleeve/Lift tunnel loops can be designed to be at the bottom or the top of the bag depending on your application. These loops on the bottom of the bag can be beneficial when height clearance is an issue.

Pros: Easiest option for forklift operators.

Cons: Specialty lift loops only usable by forklifts.

Single Loop/ Double loop

Single and double loop bags are the #1 most cost effective FIBC style. They are commonly used in Europe and some other countries. They are constructed using tubular fabric and does not require lift loops to be sewn onto the bag. Rather, the lift loops are created using colored sleeves. They are easy to handle and compatible with fully automated bagging equipment.

Pros: Most cost effective option, easy to handle

Cons: The loop must be reinforced

Fully belted loop

Fully belted loops can be found on tubular or “circular” bag constructions. The loops are sewn around the body and the bottom and form 4 or 2 lifting loops at the top of the bags. With Fully belted loops, FIBCs become more durable and stronger. Normally fully belted bulk bag are use to transport heavy weight material like ore or metal.

Pros: Strong and durable

Cons: More expensive

Thanks for reading about the most common types of flexible intermediate bulk container lift loops!