Sand is a naturally granular material composed of fine grains of rock and minerals. Sand has many different uses but it is mostly used in the industrial and construction sectors. Some types of sand (such as yellow sand) are one of the key ingredients in the concrete’s production. Besides, sand is also used in the production of glass. In many countries, jumbo bags are chosen by manufacturers to transport and store sand.

FIBC bags for sand are currently used for export purposes, circulating between sand mineral processing plants and construction sites. Sand is a product with a high specific gravity, therefore, sand PP woven bags usually have a load capacity of 1000kg-2000kg.

Specifications of Jumbo bags for sand

1. Structure:

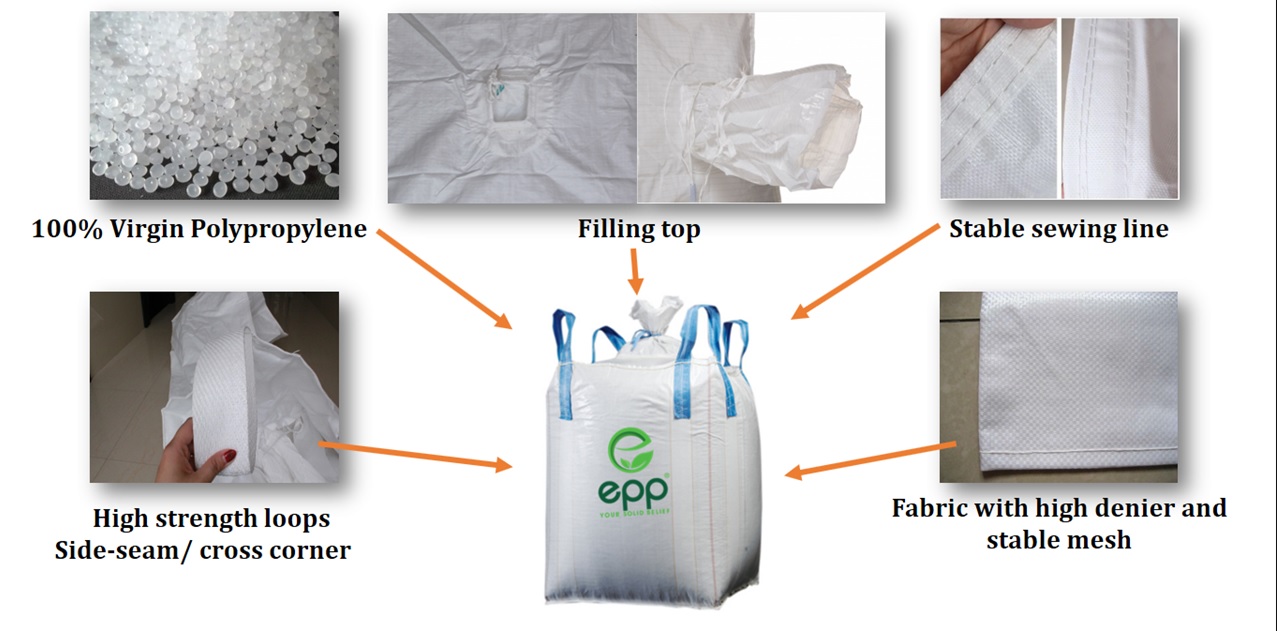

Bulk bag for sand (big bag, FIBC, jumbo bag) from EPP Vietnam is made from 100% virgin PP (Polypropylene) woven fabric with 5 parts:

Top + Body + Bottom + Loops + Liner (or coated)

Top: Filling spout or skirt cover to prevent product spillage.

Body: The big sand bag usually is a tubular or Upanel FIBC, Fabric is 150-200 GSM to ensure a safe load.

Bottom: The bottom of bulk bag for building sand usually has a spout with Star Closure & Petal Cover for easy opening and closing when unloading.

Loops: 1 ton PP woven bag for sand usually has 4 cross corner loops or fully belted loops. In addition, it can be sewn with 2 more straps for loading and unloading by cranes in the warehouse or at the port.

Liner: Depending on customer requirements, the jumbo bag will have an inner PE liner to make the bag moisture and water resistant.

.jpg)

Moreover, the Building Sand Bulk Bag is also sewn with an A4 document pocket keeping product information and notes.

2. Size:

The big bag of sand usually has a common size:

Jumbo bag for 1 ton of raw sand, construction sand: Size 90cm x 90cm x 110cm or 90cm x 90cm x 120cm.

FIBC bag for 1 ton of processed sand, titanium sands, silica sand: Size 80cm x 80cm x 80cm or 70cm x 70cm x 80cm. This is the standard size of jumbo bags for export sand.

Color, printing

In terms of color, builders bag for sand are usually white or beige. Big bag containing sand can be flexo printed from 1 to 4 colors on 1-2 sides of the bag.

3. Technical standards

All sand PP sacks produced at EPP Vietnam's factories are of high quality and meet the necessary standards:

Ensuring safety factor according to European ISO 9001:

+ Safty Factor 5:1 for single use

+ Safty Factor 6:1 for reusable bag

+ UV protection up to 1600 hours.

4. User Manual

Filling:

Step 1: Stabilize the jumbo bag on the packing rig

Step 2: Put the filling spout or skirt cover to the packing hopper

Step 3: fill sand in jumbo bags

Step 4: Move the bag outside and close the filling spout or skirt

Discharge:

Step 1: stablize the jumbo bag containing sand on the discharger, with a bottom lifting platform

Step 2: Untie the drawstring at the bottom, open the lotus wing to bring out the discharge spout

Step 3: Discharge almost all of the goods, then shake to fully release

If you need jumbo bags for sand, do not hesitate to contact us now.

EPP Vietnam - Supplier of jumbo bags with high quality, professional service and the most competitive price in Vietnam.

🌐Website: https://lnkd.in/ge2jSCN

📲Ms. Jennifer: +84 962 055 998 - sales02@epp.vn

📲Ms. Lee: +84 98 141 9896 – sales01@epp.vn

.png)