1 &2 Loop big bags are the most advantageous bigbag types. FIBCs with 1 or 2-point lifting are simpler by design and more economical than FIBC (Big Bags) with 4 lifting loops. While the simple construction facilitates the usage, various fabric widths permit a wide volume range. Its unique design provides the maximum loading capacity at a minimal cost and consequently assures advantages in freight cost as well. This bulk bags can be used for non-hazardous goods and hazardous goods classified as UN.

APPLICATION

1 or 2 lifting loops bulk bags is mostly used for packing fertilizer (e.g. Urea, Nitrogen,…) and in the chemical industry, various types of grains, seeds, briquettes, pellets, cement and other materials.

CONSTRUCTION

One and two point big bags have their body and loops made from a single piece of tubular fabric with a weight from 150 to 200g/m². Around the top of the lifting loop(s) is another piece of fabric called as a sleeve. This sleeve is available in various colours. The different colours of the sleeves on the lifting loops enables quicker product identification by the fork lift drivers and thus improves handing efficiency of the FIBC’s.

Depending on the handling process, the bigbag can be manufactured either with 1 or 2 lifting loops, with coated or uncoated fabric and with or without liner. The liners can be attached to the outer body in different ways depending on the requirements.

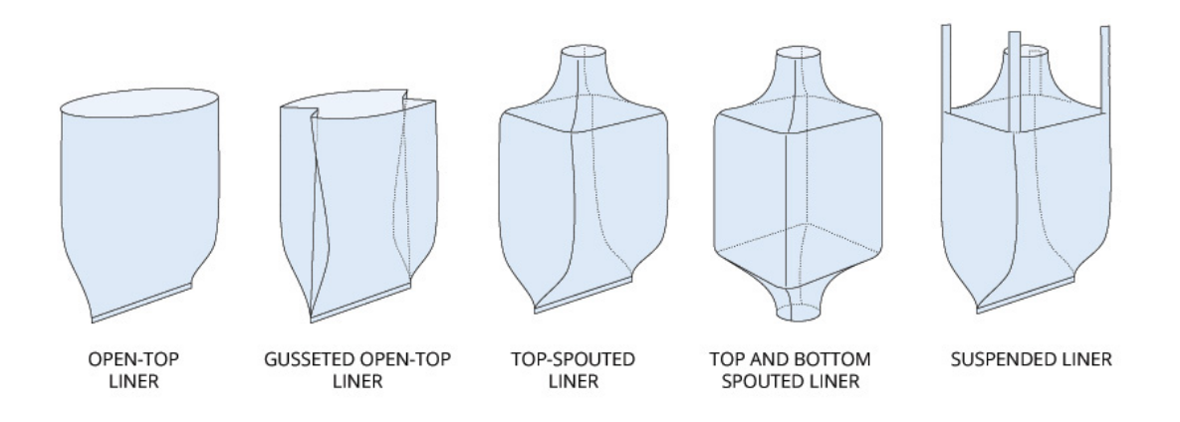

INLINER

The most common design for this FIBC is with open top, uncoated and with PE liner which can be fixed to the one and two loop big bags. PE inliner’s thickness is 60mic to 90mic. They protect the goods from moisture and product leakage.

Loose inserted tubular liner

This type is the most economical solutions for most fertilizer producers. The liner is usually welded at the bottom and open on top. The inliner can be closed with a tie which is placed on the top.

Loose inserted valved tubular liner

Similar to loose inserted tubular liner but with additional welding on top and a hole in one edge on top for filling.

Loose inserted Formliner with inlet and/or outlet spout

Formliners are inliners that are welded into the shape of a bottle which forms the inlet and/or outlet spout. Formliners can be loose inserted in the bag.

Suspended Formliners

Suspended formliners are fixed at the loops. This has the advantage that the inliner cannot move inside the big bag.

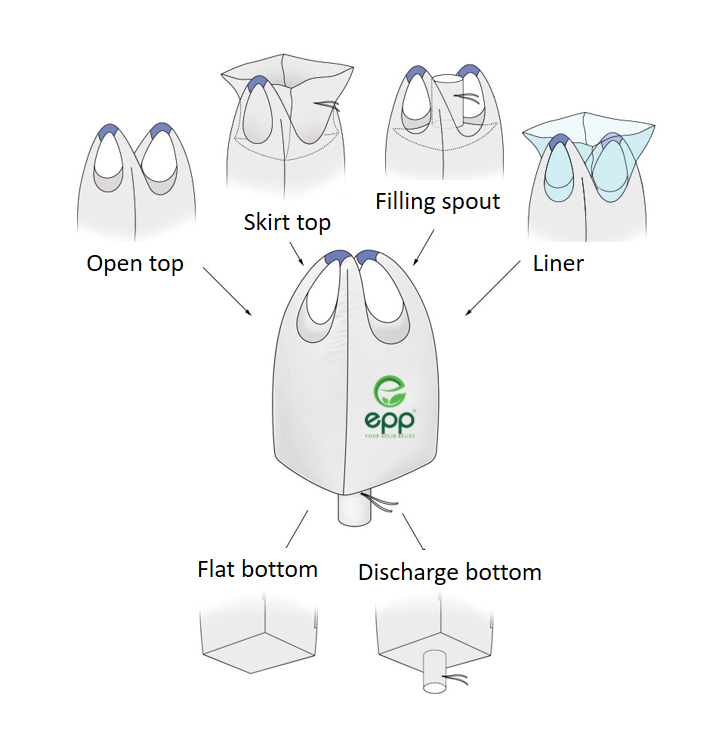

TOP OF SINGLE AND TWO LOOPS BAGS

The top of one and two loop big bags can be constructed either as an open top, with an inlet spout, or with a top skirt. However, the most common type is an open top construction with an inliner.

BOTTOM OF SINGLE AND TWO LOOP BULK BAGS

The big bag can be equipped with all types of bottom construction like discharge spout, flat bottom or others.

1 and 2 loop bulk bags are particularly suitable for packing on the roll. EPP pioneered the “Bag on Roll” technology which is increasingly the preferred system for the supply of packing products to automated filling lines.

In conclusion, 1 & 2 loops FIBCs are widely accepted for packing fertilizer, seed and other application and are preferred because they are less complicated and more economical compared to the conventional 4 loop FIBCs.

Contact our Sales team immediately:

Website: http://epp.vn/ https://eppvietnam.trustpass.alibaba.com/

Mrs Charlie: +84 986 002 888 - sales@epp.vn