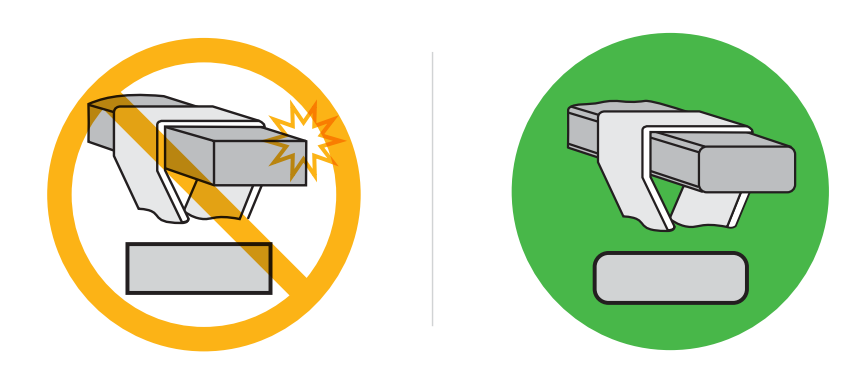

First, the hooks, spreader bars or other devices used for lifting, should have rounded edges and/or protective covers.

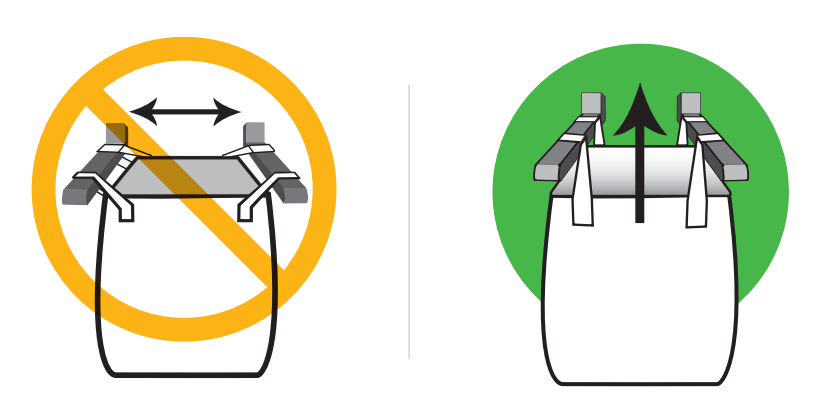

When lifting FIBCs with a fork lift truck, be sure the fork lift tines are spaced correctly. All lifting loops, sleeves, or other lifting devices should be vertical, so no damaging lateral forces will be created. Be sure the lifting loops are not twisted.

The fork lift truck must be suitable for the load to be carried. When traveling with a FIBC hanging from the fork lift tines, there is a danger of the truck becoming unstable. The bulk bags should be held close to the mast and as low as possible with the mast tilted slightly backwards. Make sure the FIBC body will not be damaged by the wheels of the truck. The load should not restrict the view of the driver.

To right a big bag that has toppled on its side, an endless fabric sling, wound through all the lifting loops, should be used. Besides, when suspending FIBCs you should remember never use fewer lift loops, sleeves, etc., than have been provided. Any attempt to lift the FIBCs using fewer loops than those provided, may result in the loops being torn off.

Never gather loops to lift with one hook, unless the Super sack is specifically designed and approved by the manufacturer for doing so.If lifting with one hook, slings or other lifting devices must be used to keep the loops vertical and prevent damaging lateral forces.

Hope that all the information has been provided may help you somehow to avoid damages to your 1 ton jumbo bags. Please contact us if you are looking for a high quality FIBC.